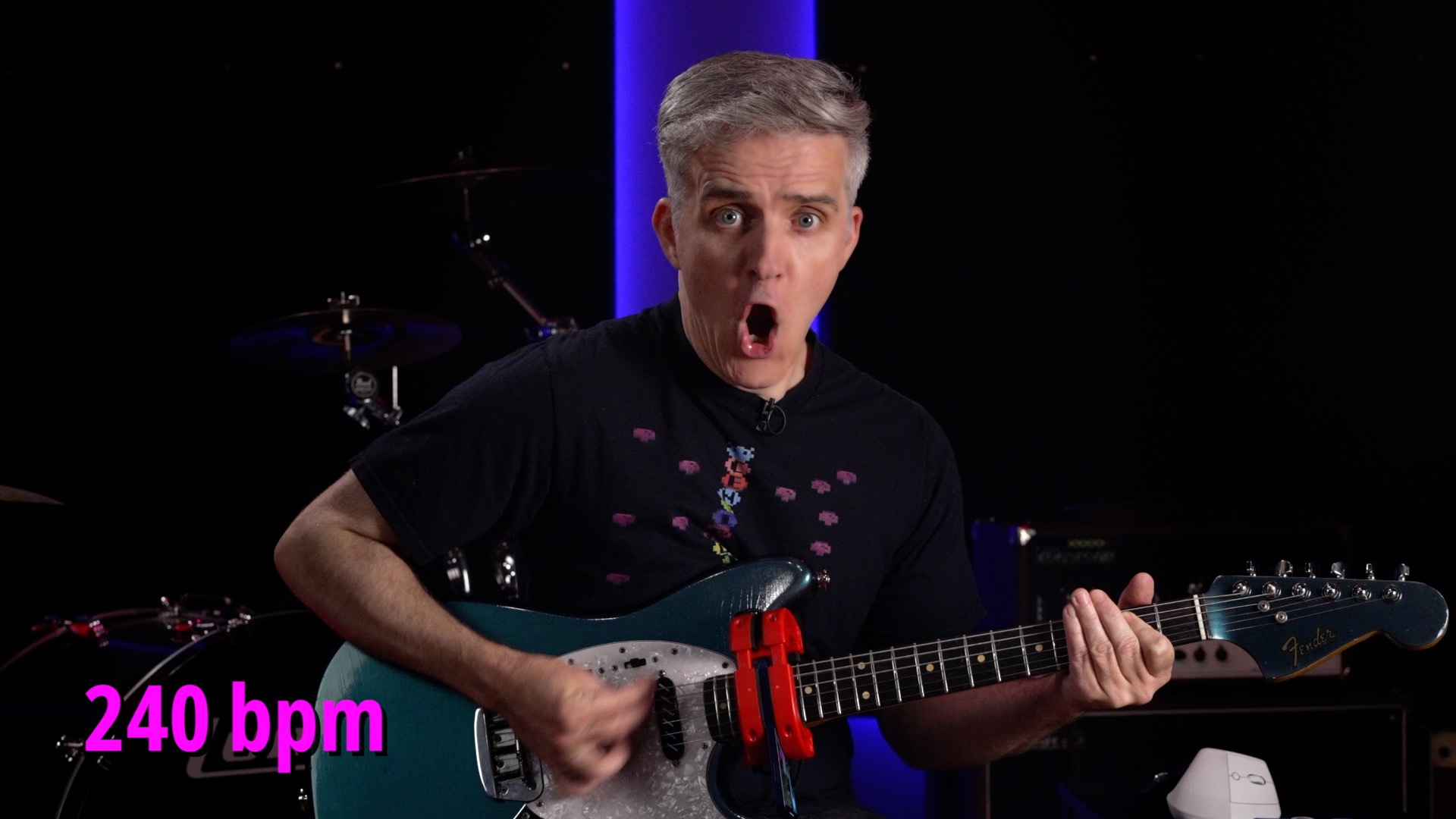

It’s easy to assume that your playing is sloppy, slow, or fatiguing because you haven’t put in enough practice time. But what if the real reason is that you’re simply doing it wrong? How can you tell the difference?

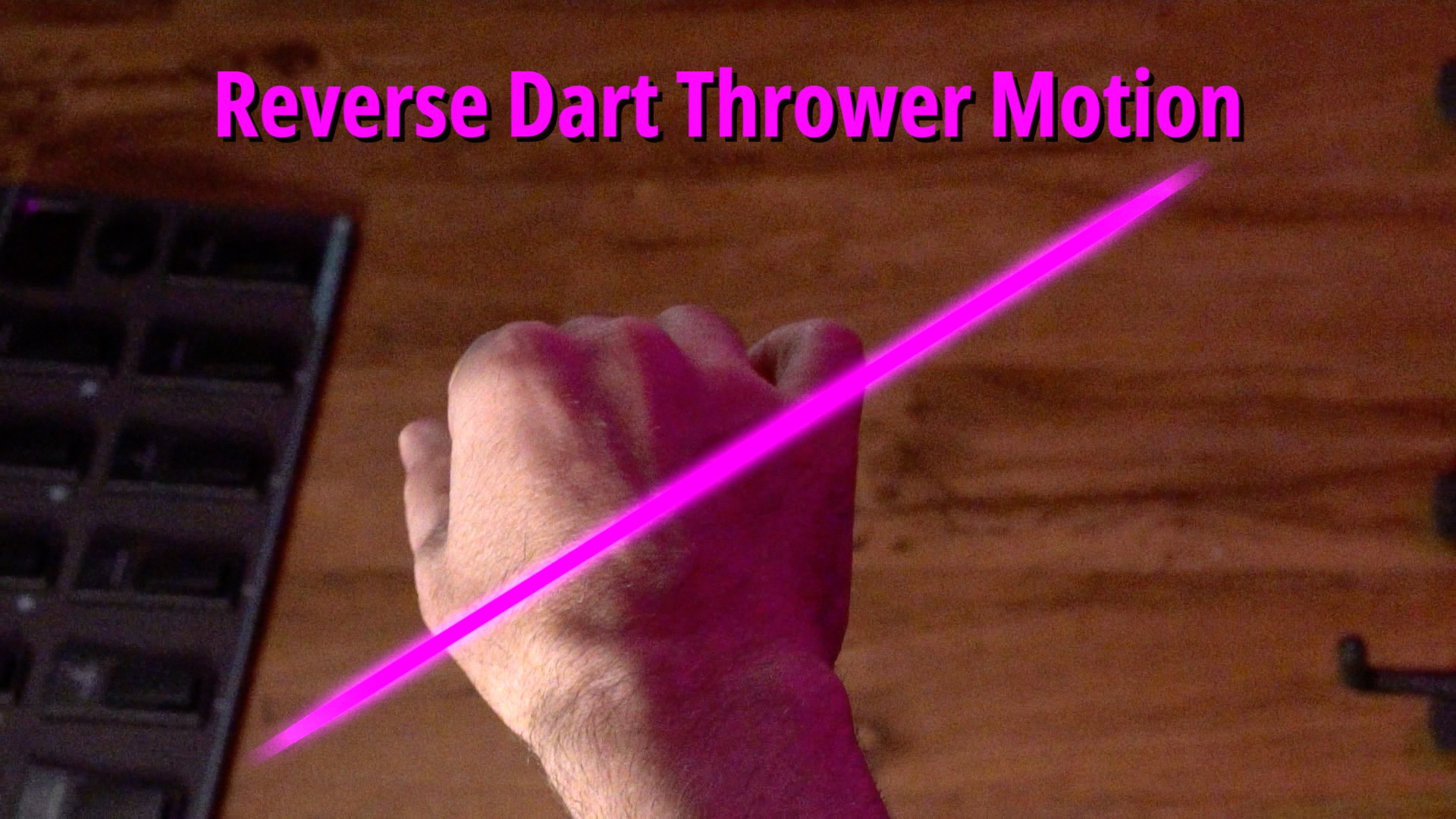

In our latest update to the Pickslanting Primer, “Choosing A Technique”, we address the critical issue of evaluating the performance of the technique you’re currently using — or the one you’re trying to learn. This update arrives alongside a large batch of additional lessons and usability improvements that we’ve been rolling out in pieces over the last several months.

Read More